The true cost of reactive facility management: Why “wait until it breaks” is breaking your budget

The true cost of reactive facility management

- March 13, 2025

- 8:42 am

- István Csányi

It’s 2:30 AM when your phone jolts you awake. The production line has ground to a halt – again. An overheated HVAC system has caused critical equipment to shut down, and now, your facility is hemorrhaging thousands of dollars with every passing hour. As you throw on clothes and head to the plant, you can’t help but wonder: Could this crisis have been avoided?

The answer, increasingly, is yes – but not with the traditional facility management approaches that still dominate industrial operations today.

The hidden financial impact of reactive maintenance

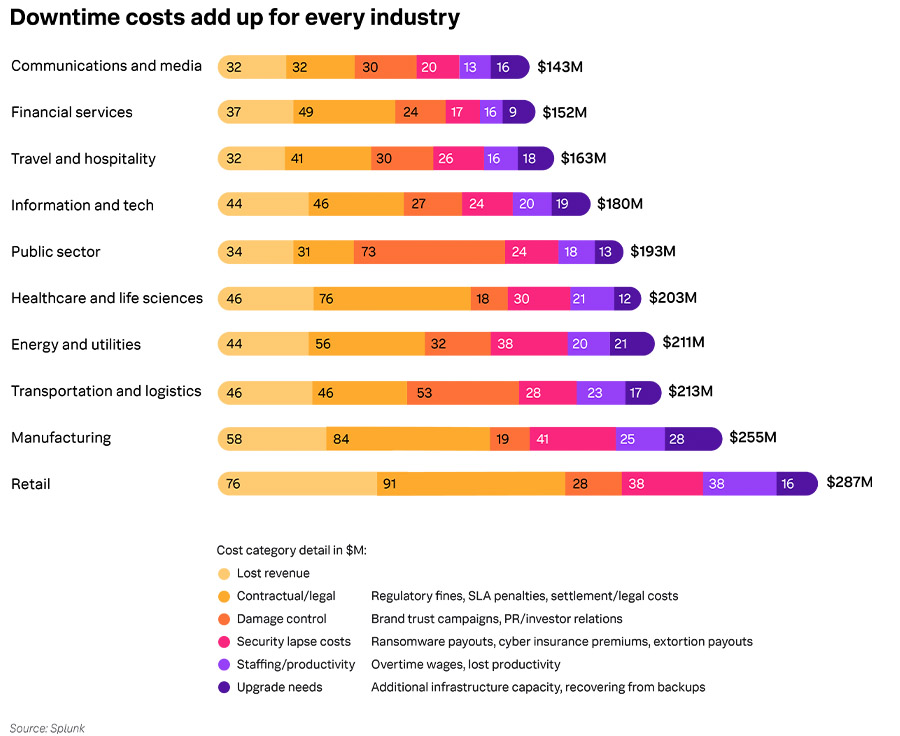

Manufacturing downtime isn’t just an operational inconvenience – it’s a financial nightmare directly impacting production targets, customer satisfaction, and the bottom line. Recent industry research shows that a typical large-scale manufacturing plant experiences between 250 and 500 hours of unplanned downtime annually. Approximately 5 to 10% of the total production capacity is lost simply because equipment and facilities aren’t properly maintained or monitored.

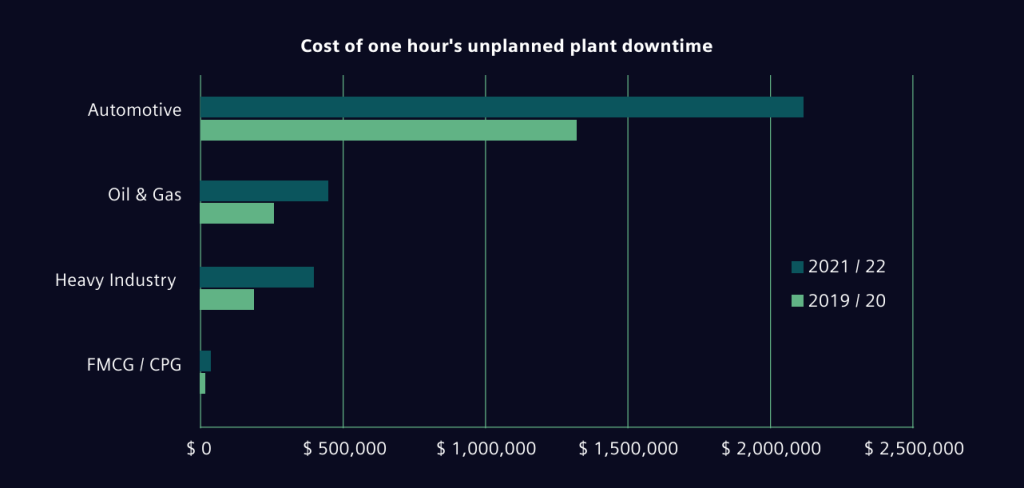

When we examine the direct financial consequences of reactive maintenance:

Automotive manufacturers lose approximately $22,000 per minute of downtime – equating to $1.3 million per hour

Food and beverage facilities face costs of roughly $30,000 per hour when production stops

Oil and gas operations experience even steeper losses, with downtime costing between $38,000 to $88,000 per hour

A single unexpected equipment failure typically costs factories between $30,000 and $50,000 in immediate repairs, not including production losses.

Across heavy industries, maintenance costs are rising at 7-9% annually. Reactive maintenance is 3-5 times more expensive than planned preventive maintenance strategies. The total cost of downtime, including ripple effects throughout the supply chain, often reaches 5-15 times the repair cost.

Yet, despite these sobering statistics, up to 80% of industrial facilities still operate primarily in reactive mode – essentially, “waiting until it breaks.” This approach persists even though it is the most expensive maintenance strategy in the long run.

“We thought we were saving money by postponing maintenance until absolutely necessary,” admits Carlos, a production manager at a mid-sized automotive parts manufacturer. “Our financial team actually rewarded us for keeping maintenance budgets low each quarter. But after calculating the true cost of three major breakdowns last year – including emergency repairs, production losses, overtime pay, expedited shipping to meet customer deadlines, and damaged client relationships – we realized our ‘cost-saving strategy’ was actually costing us nearly $2 million annually.”

Carlos’s experience represents a typical pattern across manufacturing sectors. A 2023 study from Aberdeen Group revealed that companies employing reactive maintenance strategies spend an average of 40% more on their overall maintenance programs than those with proactive approaches. These reactive organizations experience 43% more downtime and operate with assets with 3.5 years shorter operational lifespans.

Key barriers to proactive facility management

The persistence of reactive facility management isn’t simply due to organizational inertia. Several fundamental limitations in traditional approaches create substantial barriers to improvement. Understanding these challenges is essential for any organization looking to break free from the cycle of crisis-driven maintenance.

1. Fragmented systems and information silos

Most industrial facilities operate with a patchwork of management systems that rarely communicate effectively with each other. HVAC controllers operate independently from electrical systems. Production equipment generates data that never connects with facility infrastructure insights. Maintenance records exist in spreadsheets or paper logbooks disconnected from real-time operations.

This fragmentation creates operational blind spots where minor issues develop into significant problems.

“In our paper mill, we had one team monitoring the steam systems, another handling electrical, and a third responsible for the production equipment,” explains Thomas, a facility director with 25 years of experience. “Our steam pressure was gradually dropping, but because that system didn’t ‘talk’ to the production monitoring system, nobody made the connection that it was affecting product quality. We lost nearly $400,000 in rejected products before figuring out the root cause was a simple steam trap failure that could have been fixed for under $1,000.”

The technical architecture of most industrial facilities compounds this problem. Legacy systems, often installed decades apart, use proprietary protocols and closed data formats. Building automation systems rarely share data easily with manufacturing execution systems or enterprise resource planning software. This lack of interoperability means that crucial connections between facility health and production performance are unrecognized.

A Siemens study found that the average factory has 8-12 separate control systems, with data trapped in at least 5-7 formats. Even when facilities attempt to collect this information manually, the process is time-consuming and prone to errors, making real-time decision-making nearly impossible.

2. Invisible degradation and the failure horizon

One of the most insidious aspects of equipment deterioration is its often invisible progression. Many critical components don’t fail suddenly – they degrade gradually over weeks or months, with subtle signs that traditional inspection methods miss.

Consider a manufacturing facility’s compressed air system – the often-overlooked “fourth utility” that powers countless pneumatic tools and processes. A small leak might start as a pinhole, causing minimal pressure drop that escapes routine detection. Over time, the leak grows, forcing compressors to work harder and consume more energy. When the pressure drop finally becomes noticeable to operators, the facility may already be wasting 20-30% of its compressed air capacity, representing tens of thousands in unnecessary energy costs annually.

“We discovered we were spending an additional $157,000 per year in electricity just to compensate for air leaks throughout our facility,” notes Jennifer, an operations manager at a packaging plant. “Those leaks developed so gradually that nobody noticed until we conducted a comprehensive audit. The frustrating part is that we could have addressed those leaks for less than $15,000 if we’d caught them early.”

This pattern repeats across virtually all facility systems – subtle degradation in HVAC efficiency, slowly increasing motor vibration, gradual corrosion in pipework, or minor changes in electrical load patterns. Traditional management approaches simply lack the sensitivity to detect these early warning signs before they escalate into equipment failure.

3. The energy waste epidemic

Traditional facility management approaches are notorious energy wasters, and as energy costs rise, this problem has become increasingly expensive. Static temperature set points fail to account for changing conditions or operational needs. Lighting and climate systems run at full capacity regardless of occupancy or production schedules. Equipment operates at suboptimal settings because no one has visibility into the efficiency data.

The cost is staggering. According to a 2023 Schneider Electric report, industrial facilities typically waste 15-30% of their energy due to inefficient management. Energy-intensive operations like metal processing, data centers, or chemical manufacturing can translate to millions of dollars annually.

“Our chemical processing plant used a standard 72°F setpoint throughout the facility year-round, which was our protocol for decades,” says Robert, an engineering manager at a specialty chemicals company. “When we finally analyzed our processes in detail, we discovered that our mixing area actually operated more efficiently at 75°F, while our packaging area performed better at 68°F. By implementing zone-specific temperature management, we reduced our HVAC energy consumption by 22% without negatively impacting operations.”

Even more concerning is how energy waste compounds maintenance issues. Equipment running at higher-than-necessary power loads experiences accelerated wear and tear. HVAC systems struggling against process heat without proper coordination break down more frequently. Motors that never get rest cycles burn out faster. The result is a vicious cycle where energy inefficiency directly contributes to maintenance failures, leading to greater energy waste.

4. The human error factor

Even the most diligent maintenance staff cannot be everywhere at once. Traditional management approaches rely heavily on manual inspections and human judgment, which are inherently limited and inconsistent processes.

“Our maintenance team was doing everything by the book,” explains Sarah, operations director at a pharmaceutical manufacturing facility. “But they simply couldn’t detect the gradual pressure drop in our cooling system, which eventually led to a $1.2 million batch contamination. The warning signs were not visible during standard inspections. Even worse, we had multiple technicians recording readings slightly differently, so we couldn’t establish a reliable baseline for ‘normal’ operation.”

The human element introduces several unavoidable limitations:

-

Inspection inconsistency: Different technicians may focus on different aspects of equipment or interpret readings differently

-

Confirmation bias: After repeatedly finding equipment in good working order, technicians may become less thorough or dismiss subtle changes

-

Documentation variability: Handwritten notes, inconsistent terminology, and varying levels of detail make it difficult to establish trends

-

Limited sampling: Manual inspections represent a tiny snapshot of equipment operation, missing issues that appear only under specific conditions

-

Knowledge retention: Critical system insights often remain locked in the minds of veteran employees, creating vulnerability when they retire or change positions

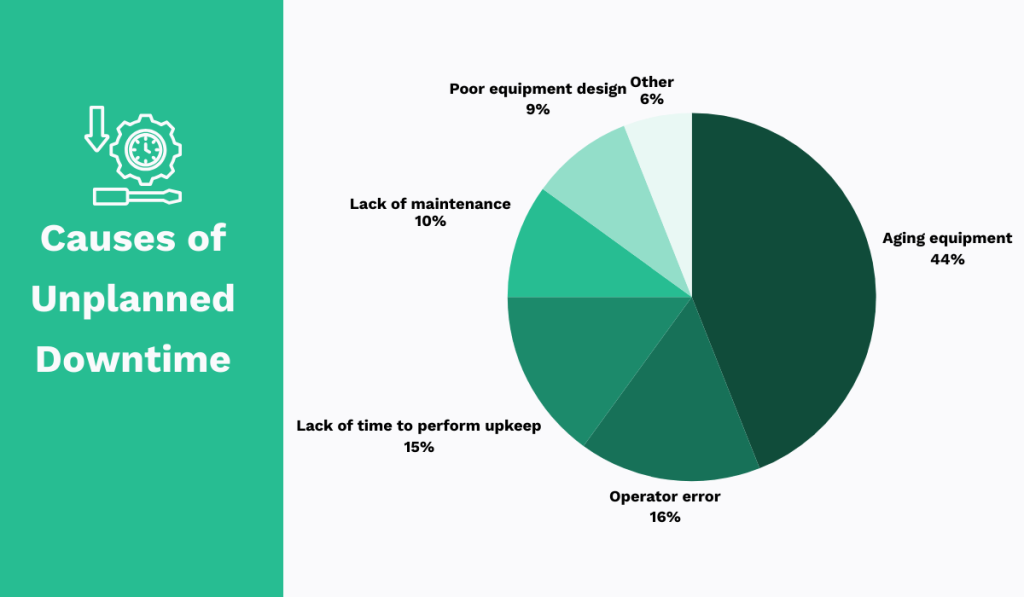

A 2022 study published in the International Journal of Industrial Engineering found that human factors contribute to approximately 60% of maintenance-related equipment failures. The study noted that even with extensive training, human inspectors can typically only identify about 40-55% of developing equipment issues before they reach critical failure stages.

5. Budget constraints and the false economy of maintenance

Perhaps the most persistent barrier to improved facility management is the misalignment between budgeting practices and operational realities. Maintenance departments are typically viewed as cost centers rather than strategic assets, leading to continual pressure to minimize spending.

“Every year during budget planning, we faced the same battle,” recalls Michael, former maintenance director at a large manufacturing plant. “Finance wanted to know why we needed to spend money on equipment that wasn’t broken yet. They’d point to last year’s emergency repair costs as evidence that we could handle problems as they arose. What they never factored in was the production downtime, rushed shipping fees, overtime labor, and customer penalties that didn’t show up on the maintenance department’s ledger but cost the company millions.”

This disconnect creates a false economy where preventive measures appear unjustifiably expensive when viewed in isolation. Companies consistently underfund proactive facility management initiatives without accounting for the full cost impact of failures across all business operations.

The accounting structures of most organizations exacerbate this problem. Capital expenditures for system upgrades face intense scrutiny and high ROI thresholds, while emergency repairs come from operational budgets that face less resistance during crises. The result is a perpetual cycle of underinvestment in facility infrastructure until catastrophic failure forces action.

The cascading consequences of reactive management

The consequences of reactive facility management extend far beyond immediate repair costs, creating cascading effects throughout the organization and its broader ecosystem:

Extended downtime and production losses

Diagnosing problems takes longer without systematic monitoring – sometimes days rather than hours. Modern industrial equipment and facilities involve complex, interdependent systems that can be difficult to troubleshoot without proper baseline data or historical performance tracking.

“When our main air handler failed unexpectedly, it took nearly three days to diagnose the root cause,” shares David, a facility manager at a semiconductor manufacturing plant. “The symptoms appeared in multiple systems simultaneously, and without trending data to show which issue appeared first, our team was essentially guessing. Each hour of diagnostic time cost us approximately $50,000 in lost production.”

These extended troubleshooting periods can devastate organizations operating in just-in-time manufacturing environments or those with tight production schedules. The ability to quickly pinpoint problems – or address them before they cause shutdowns – represents one of the most significant advantages of moving beyond reactive management.

Shortened equipment lifespan and premature capital expenditures

Systems operating outside optimal conditions degrade faster, requiring earlier replacement and creating unexpected capital expenditure requirements that disrupt financial planning.

According to a comprehensive study from the Marshall Institute, adequately maintained equipment lasts 30-40% longer than equipment managed under reactive strategies. This difference can represent millions in accelerated replacement costs for capital-intensive industries like manufacturing, mining, or energy production.

“We were replacing our conveyor drive motors every 18-24 months under our reactive maintenance program,” notes William, an engineering director at a distribution center. “After implementing a more systematic approach with regular monitoring and preventive maintenance, those same motors now last 4-5 years. Across our facility with dozens of these drives, we’ve saved over $600,000 in replacement costs alone over a five-year period.”

These premature replacements create a particularly insidious financial drain because they often occur outside regular budgeting cycles. As a result, organizations are forced to divert funds from strategic initiatives to cover emergency capital expenses.

Increased safety risks and regulatory exposure

Equipment failures don’t just impact production – they create potential safety hazards for employees and may trigger regulatory scrutiny.

A 2024 report from the Occupational Safety and Health Administration (OSHA) found that facilities with primarily reactive maintenance strategies experienced 3.5 times more safety incidents than those with comprehensive preventive programs. These incidents range from minor injuries to potentially catastrophic events, particularly in facilities handling hazardous materials or high-energy processes.

Beyond the human cost, these safety incidents have significant financial implications, including workers’ compensation claims, potent regulatory fines, increased insurance, and litigation expenses. They also frequently trigger intensive regulatory inspections that may uncover other compliance issues.

“After a pressure vessel failure injured two employees, we faced not only the immediate emergency response but a top-to-bottom OSHA inspection that identified 17 other compliance issues across our facility,” recalls Patricia, a safety director at a chemical processing plant. “The initial incident and resulting violations cost us over $950,000 in fines, repairs, and required upgrades – all problems that our own preventive program would have identified and addressed for a fraction of that cost if properly implemented.”

Environmental impact and sustainability concerns

As organizations focus on environmental performance, reactive maintenance’s ecological footprint becomes increasingly problematic. Equipment operating inefficiently consumes more energy and resources, and sudden failures can lead to releases or contamination.

A study published in the Journal of Cleaner Production found that reactive maintenance strategies increased overall carbon emissions by 15-25% compared to preventive approaches across various industrial sectors. The study cited increased energy consumption from degraded equipment, emergency repair activities, expedited shipping of replacement parts, and waste from prematurely discarded components as primary contributors to this environmental impact.

These environmental concerns extend beyond corporate social responsibility to tangible business risks, including regulatory compliance issues, potential fines, and damage to brand reputation among environmentally conscious customers and investors.

Customer dissatisfaction and market position erosion

Production delays impact delivery schedules and damage relationships, often with long-term consequences for market position and customer loyalty.

“We lost a $2.3 million annual contract after three consecutive late deliveries caused by equipment failures,” shares Robert, a business development director for an industrial parts manufacturer. “The customer was sympathetic to occasional problems, but they ultimately couldn’t risk their own production schedules. The frustrating part is that all three failures were preventable with proper monitoring and maintenance.”

In today’s competitive global market, customers have increasingly little tolerance for supply disruptions. The reputational damage from unreliable delivery performance can persist long after the underlying facility issues are resolved, creating a lasting drag on sales efforts and customer retention.

Building a proactive facility management strategy

The most forward-thinking industrial organizations recognize that maintaining status quo facility management is inefficient and increasingly unsustainable in a competitive global market where margins continue to tighten and customer expectations for reliability rise.

The first step toward improvement isn’t necessarily implementing cutting-edge technology but changing the fundamental approach from reactive to proactive. This means systematically analyzing current operations, identifying critical points of potential failure, and implementing comprehensive monitoring before crises occur.

“We started small,” explains Maria, a plant manager who successfully transformed her facility’s maintenance strategy. “We identified our ten most critical pieces of equipment and began monitoring them consistently – nothing fancy, just regular measurements with clear documentation. Within six months, we prevented three major failures that would have shut down production. That early success gave us the credibility to expand the program facility-wide.”

Organizations that successfully transition from reactive to proactive facility management typically follow a similar progression:

-

Assessment and prioritization: Conduct a thorough evaluation of all facility systems, identifying critical equipment and potential failure points based on operational impact

-

Establish baselines: Document normal operating parameters and conditions for key systems to enable meaningful comparison over time.

-

Implement systematic monitoring: Develop consistent inspection and data collection procedures – even manual processes can yield significant improvements before investing in automated systems.

-

Develop preventive protocols: Create standard procedures for addressing issues at early detection stages rather than waiting for failure.

-

Train and empower staff: Ensure maintenance personnel understand the technical aspects of preventive maintenance and the business rationale behind the shift.

-

Document and demonstrate value: Carefully track prevented failures and associated cost avoidance to build organizational support.

-

Gradually integrate systems: Work toward breaking down the silos between facility systems for more comprehensive visibility.

-

Refine based on results: Continuously improve processes based on outcomes and data.

This evolutionary approach allows organizations to build momentum through early wins while developing the organizational capabilities needed for more sophisticated facility management strategies. Rather than treating the transition as a massive project requiring substantial upfront investment, successful organizations view it as a capability-building journey with incremental benefits at each stage.

The transition inevitably requires some initial investment of financial and human resources, but the returns typically begin accruing quickly. A survey of manufacturers by Plant Engineering found that organizations implementing structured preventive maintenance programs saw positive ROI within an average of 6-9 months. Maintenance costs decreased by 12-18% in the first year despite the additional preventive activities.

Breaking down silos: The next step in facility management evolution

As we’ll explore in our next post, breaking down information silos is crucial to gaining the visibility needed for genuinely effective facility management. When HVAC data can inform production planning, when electrical usage patterns can trigger maintenance activities, and when all systems communicate within an integrated framework, industrial facilities can begin to escape the costly trap of reactive management.

Considering that the average manufacturing plant loses 5-10% of its production capacity to preventable downtime, the opportunity cost of maintaining the reactive status quo becomes clear. Organizations that successfully transition to proactive facility management don’t just reduce costs – they gain a significant competitive advantage through improved reliability, extended asset life, and enhanced operational efficiency.

This is the first in a four-part series examining industrial operations’ hidden challenges today. Join us next week for Part 2: “Breaking Down Silos: The Integration Challenge in Industrial Operations.”

References

-

Facilio. (2025). Cut Reactive Maintenance Costs & Delight Clients with Connected CaFM: A Guide for IFM Leaders.

-

Simões, J., Gomes, C., & Yasin, M. (2016). A literature review of maintenance performance measurement. Journal of Quality in Maintenance Engineering.

-

PMC. (2023). Strategic selection of maintenance type under different conditions. PMC Articles.

-

ClickMaint. (2023). React and Restore: A Comprehensive Guide to Reactive Maintenance.

-

DIVA Portal. (2016). Strategic Maintenance Development Focusing on Use.

-

AkitaBox. (2025). Preventive vs. Reactive Maintenance: What’s the Difference?

-

Supriatna, A., Singgih, M., & Kurniati, N. (2016). Preventive maintenance strategies: Literature review and directions.

Business Development at Machine Intelligence Zrt. Innovation professional with 25+ years of experience in IT solutions and product strategy. Science history enthusiast and digital fabrication hobbyist specializing in 3D printing, laser cutting, and CNC. Holds MSc degrees in Chemistry and Physics from the University of Szeged.