Breaking down silos: The integration challenge in industrial operations

Breaking down silos: The integration challenge in industrial operations

- March 24, 2025

- 10:41 am

- István Csányi

The production line has been down for four hours. In the maintenance office, three teams argue over who owns the problem. The electrical department insists their systems show no anomalies. The HVAC team confirms cooling systems are operating within parameters. Production supervisors point to equipment failure warnings but can’t explain why. Meanwhile, the clock ticks—€42,000 ($50,000) in losses every hour.

Later, after production finally resumes, the post-mortem reveals an uncomfortable truth: a cooling system operating “within parameters” was insufficient for the unusually high production volumes planned that day. The production team never informed facilities about the increased load. The HVAC control system had no visibility into production schedules. And no one’s monitoring system could see the complete picture across departmental boundaries.

The culprit wasn’t a single system failure but the invisible gaps between systems.

The Fragmented Reality of Industrial Operations

In today’s industrial facilities, critical systems exist as islands of automation—separate technologies installed over decades, speaking different languages, and supervised by individual teams. While the first installment of our series explored how reactive maintenance approaches drain budgets and productivity, this disconnection between systems creates equally expensive—though often less visible—costs.

The numbers tell a troubling story. According to a comprehensive Siemens study, the average manufacturing facility operates with 8-12 separate control systems, with critical operational data trapped in at least 5-7 formats. Research from the International Society of Automation (ISA) indicates this fragmentation exists across global industrial operations, from automotive plants in Germany to electronics factories in Malaysia and oil refineries in Saudi Arabia. This fragmentation isn’t just an IT inconvenience—it fundamentally undermines operational visibility, efficiency, and decision-making.

“Our facility has over €12 million in sophisticated automation equipment, but it’s like having fifteen expert specialists who all speak different languages and refuse to talk to each other,” explains Richard, operations director at a medical device manufacturing plant. “When things run smoothly, we manage. But when problems arise, this fragmentation turns minor issues into production nightmares because no one can see the complete picture.”

The cost of this fragmentation is staggering but often hidden. McKinsey Global Institute research indicates that integrated industrial operations typically achieve 15-20% greater overall equipment effectiveness (OEE) than siloed facilities. This translates to millions in recoverable lost productivity hidden in the gaps between systems for a mid-sized manufacturer.

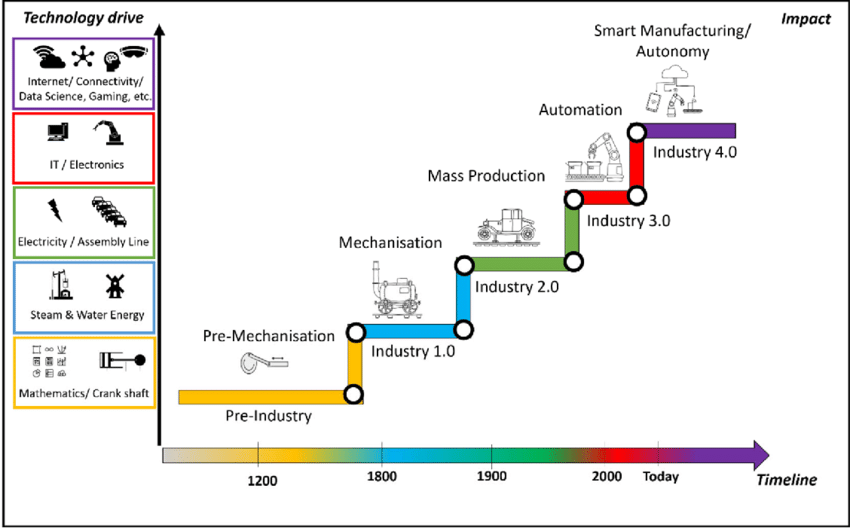

Historical Evolution of Industrial System Fragmentation

Today’s fragmentation didn’t happen overnight. It evolved over decades as technologies advanced at different rates and facilities made incremental improvements.

In typical industrial environments, automation arrived in waves: basic PLCs in the 1970s, computerized maintenance management systems (CMMS) in the 1980s, manufacturing execution systems (MES) in the 1990s, building automation in the 2000s, and Industrial IoT more recently. Each technology wave had proprietary protocols, data structures, and specialized teams.

“Our facility is like an archaeological dig of industrial technology,” notes Thomas, a facility engineer at a food processing plant. “We have thirty-year-old PLCs communicating via Modbus, building systems using BACnet, newer equipment with EtherNet/IP, and custom database systems storing critical information. None of these systems were designed to talk to each other.”

This technological evolution created a fundamental integration challenge that most facilities have yet to overcome. While each system may be sophisticated within its domain, its isolation creates blind spots that undermine the potential of even the most advanced individual components.

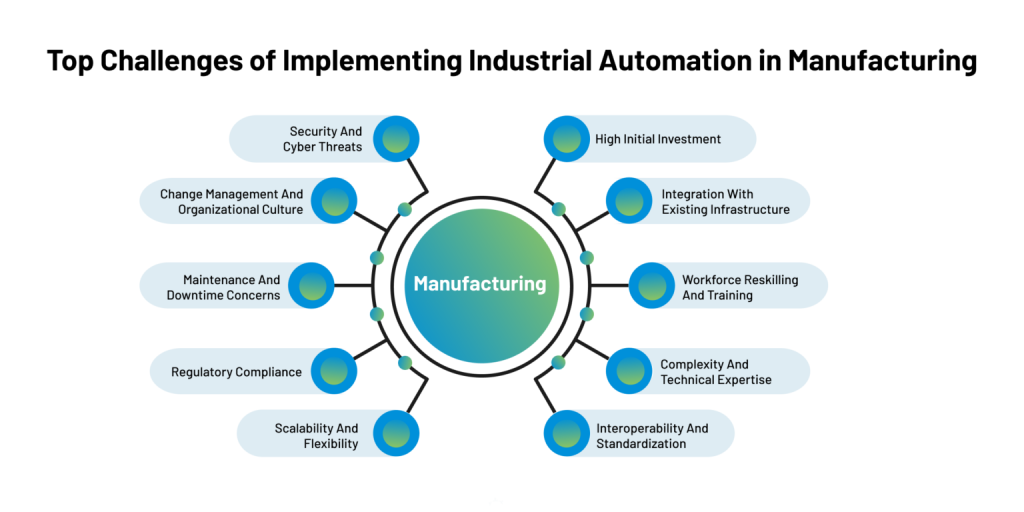

The Four Critical Integration Gaps in Modern Industrial Operations

While industrial fragmentation affects facilities in countless ways, four fundamental gaps create the most significant operational challenges and financial losses.

1. Physical System Isolation: When Hardware Doesn’t Talk

At the most basic level, critical physical systems in industrial facilities—HVAC, electrical distribution, water management, compressed air, production equipment, and material handling—typically operate as independent entities with minimal direct communication.

“Our painting line requires precise temperature and humidity control to maintain finish quality,” explains Maria, a quality manager at an automotive components manufacturer. “But our climate control system lacks visibility into production schedules or paint chemistry requirements. When production changes formulations or increases line speed, the environmental controls don’t automatically adjust. Last year, this disconnect caused us to scrap nearly €335,000 in finished parts due to quality issues that could have been prevented with better system integration.”

This physical isolation means that changes in one system don’t trigger appropriate adjustments in related systems. Equipment runs without contextual awareness of broader facility conditions, and optimization opportunities remain invisible because no system can see how adjustments might benefit connected processes.

The consequences extend beyond operational inefficiency. Physical system isolation creates safety risks when critical systems lack awareness of potential hazards created by other systems. In a 2022 safety incident at a chemical processing facility, an emergency ventilation system failed to activate during a minor chemical release because the detection system could not communicate with the ventilation controls—turning a containable incident into a €1 million facility evacuation and decontamination.

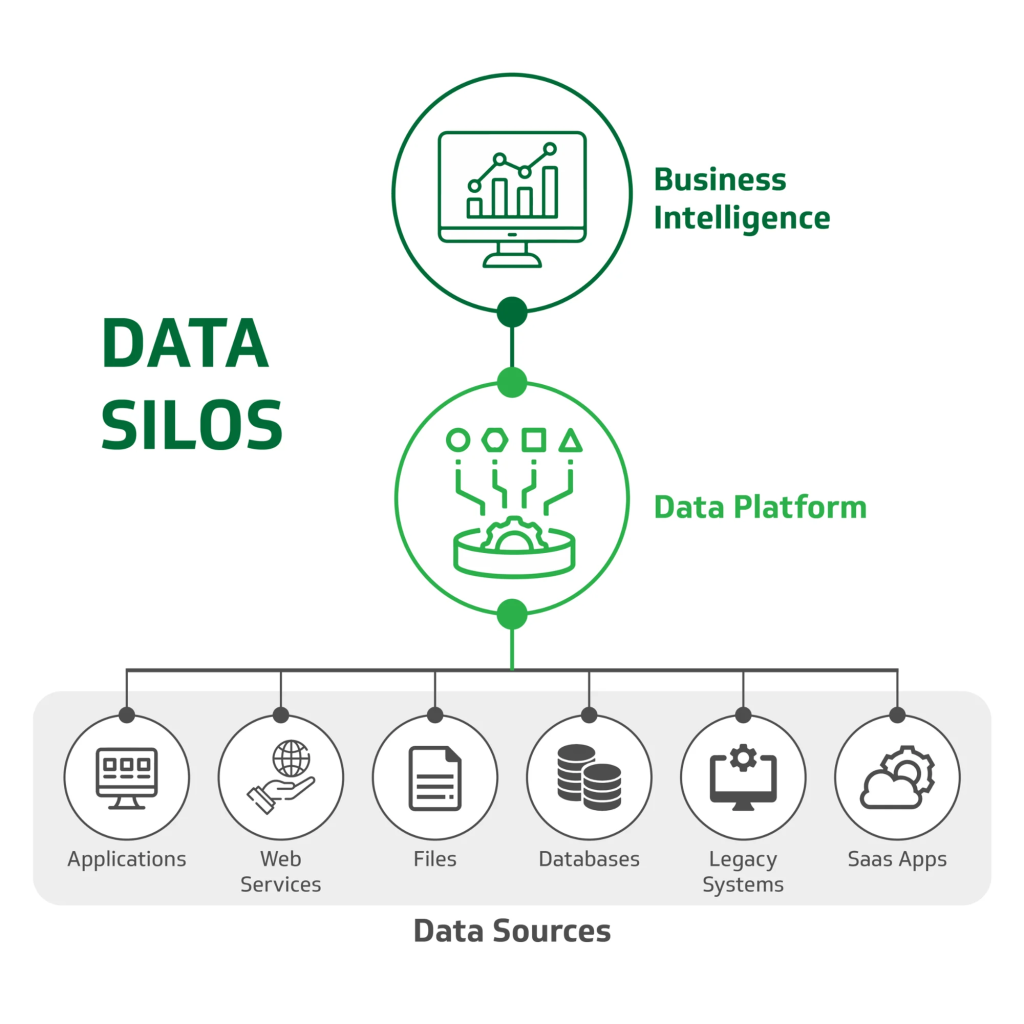

2. Data Format Incompatibility: The Tower of Babel Problem

Even when physical systems can technically connect, they often speak entirely different languages. Industrial facilities typically contain a multitude of data protocols and formats:

Proprietary PLC communication protocols from different automation vendors

Building automation systems using BACnet or similar standards

Historian databases with custom data structures

CMMS systems with their data formats

ERP and MES systems with different database architectures

Spreadsheets and paper records with unstructured information

International standards variations further complicate the situation. While some facilities follow ISA-95/IEC 62264 for enterprise-control system integration, others use the ISO 18435 framework for diagnostic and maintenance applications or the ISO 15926 standard for process plant data integration.

“We wanted to implement a simple predictive maintenance program that would alert us when the equipment was showing signs of future failure,” shares William, maintenance director at a paper mill. “But extracting and combining the necessary data from our vibration monitoring, process control, and maintenance systems proved nearly impossible because each used different time stamps, asset identification methods, and data structures. We spent more time integrating the data than actually analyzing it.”

This Babel of industrial data formats forces many facilities to resort to manual data transcription—a time-consuming process prone to errors and delays. In one documented case from a World Economic Forum manufacturing study, a power plant’s efficiency analysis required three full-time employees to collect and normalize data from different systems, adding €200,000 in annual labor costs while introducing delays that prevented timely optimization.

3. Departmental Communication Breakdowns

Technical silos inevitably create organizational silos. In most industrial operations, separate teams manage different aspects of the facility, each with their priorities, metrics, and communication channels:

Production teams focused on output and quality

Maintenance departments concerned with equipment reliability

Facilities teams managing building systems

Energy managers tracking consumption (kWh, BTUs, megajoules)

Quality assurance monitoring process compliance

IT departments overseeing networks and computers

These organizational boundaries often mirror technical ones, reinforcing the fragmentation.

“Our biggest integration challenge isn’t technical—it’s human,” admits Jennifer, operations excellence director at a consumer goods manufacturer. “Our maintenance team upgraded a critical compressor system without informing production about new pressure parameters. Meanwhile, our facilities team modified the cooling system serving that equipment without coordinating with either group. When production increased line speed, the resulting cascade of mismatched specifications caused a two-day shutdown costing over €630,000.”

Communication gaps between departments create costly blindspots. A global Plant Engineering survey spanning 17 countries found that 65% of industrial facilities report significant operational disruptions at least quarterly due to poor interdepartmental communication about system changes or operational adjustments.

These barriers extend to the daily flow of critical information. Maintenance teams don’t receive production forecasts that could help optimize preventive maintenance scheduling. Production managers lack visibility into upcoming facility work, which might affect their operations. Energy managers implement efficiency measures without understanding their impact on production capabilities.

4. Budgetary and Planning Disconnections

Perhaps the most persistent barrier to integration is how industrial operations are funded and planned. Budgets for production equipment, facility systems, maintenance activities, and technology initiatives typically fall under departmental controls with separate approval processes and success metrics.

“For three consecutive years, I tried to get funding for a unified monitoring system that would connect our production equipment with our facility systems,” recalls Robert, a former plant manager at a food processing operation. “But the project never moved forward because it didn’t fit neatly into the production capital or the facilities improvement budget. The ROI was clear when looking at the complete picture, but our budgeting process had no mechanism to evaluate cross-functional investments.”

This budgetary fragmentation creates a self-reinforcing cycle:

Separate budgets fund disconnected systems

Disconnected systems generate fragmented data

Fragmented data makes it impossible to demonstrate the full value of integration

Without demonstrated value, integrated solutions remain unfunded

The cycle of disconnection continues

The result is persistent underinvestment in integration initiatives that could deliver substantial returns but don’t align with traditional budgeting structures.

Real-World Impacts of Integration Failures

The consequences of system fragmentation extend far beyond technical inconveniences, creating tangible operational and financial impacts across all aspects of industrial operations.

Operational Inefficiencies and Hidden Waste

When systems operate in isolation, significant waste becomes normalized and invisible. Consider these documented examples from industrial facilities:

“Our production scheduling system had no connection to our energy management system,” shares Michael, an energy manager at a metal fabrication plant. “As a result, our most energy-intensive processes were regularly scheduled during peak rate periods, adding approximately €290,000 in unnecessary electricity costs annually. When we finally integrated these systems, we reduced our energy costs by 22% by shifting certain operations to off-peak hours without affecting production volumes.”

Similar inefficiencies occur throughout fragmented operations:

HVAC systems cool or heat areas during non-production periods because they lack visibility into production schedules

Compressed air systems maintain full pressure (6-8 bar/87-116 psi) during downtimes because they don’t receive production status information.

Preventive maintenance occurs too frequently or too rarely because maintenance systems can’t access actual usage data.

Equipment runs at suboptimal settings because operators lack visibility into energy consumption data.

A Deloitte global manufacturing study spanning operations in North America, Europe, and Asia found that the average factory wastes 30-40% of its capacity due to these disconnected operations. Most concerning is how these inefficiencies become accepted as “normal operating conditions” when teams lack the integrated data to identify improvement opportunities.

Delayed Problem Identification and Resolution

When systems are fragmented, identifying the root cause of problems becomes exponentially more difficult. Issues that cross system boundaries often create prolonged diagnostic challenges as different teams try to piece together a complete picture from partial information.

“A mysterious quality issue affected our pharmaceutical packaging line intermittently for months,” recalls Patricia, a quality assurance director. “Our production system showed no anomalies. Each department investigated its area and found everything ‘within specs.’ It wasn’t until we temporarily stationed representatives from maintenance, facilities, production, and quality in the same room—each with access to their respective systems—that we discovered the issue: slight variations in compressed air pressure, technically within acceptable ranges but occurring precisely when the building HVAC cycled, created enough cumulative variation to affect package sealing. This simple problem cost us over €1 million in rejected products before we connected the dots.”

According to maintenance data from the Society for Maintenance and Reliability Professionals, the diagnostic timeline for cross-system issues typically extends 300-500% compared to problems within a single system. This extended time-to-resolution directly impacts the bottom line through:

Extended production downtime

Increased troubleshooting labor costs

Unnecessary parts replacement as teams try different solutions

Quality losses as intermittent issues affect the product before being resolved

Missed Optimization Opportunities

Perhaps the most significant hidden cost of fragmentation is the inability to optimize operations holistically. Facilities cannot identify or implement many high-value improvements without integrated data and systems.

“We operated for years with each department optimizing their metrics,” explains David, operations director at a consumer packaged goods manufacturer. “Maintenance maximized equipment availability. Facilities minimized energy costs. Production maximized throughput. But when we finally implemented cross-system integration and analytics, we discovered counterintuitive optimization opportunities we’d never seen before.”

“For example, we found that slightly reducing line speed on certain products—contrary to traditional production goals—while making corresponding adjustments to temperature profiles reduced overall energy consumption by 34% and decreased maintenance issues by 26%, increasing total output and profitability despite the ‘slower’ production rate. Without integrated data across maintenance, facilities, energy, and production systems, this counterintuitive optimization would have remained invisible.”

The International Energy Agency estimates that advanced industrial facilities capture only 20-30% of potential optimization opportunities when working with fragmented systems. The remaining 70-80% require cross-system visibility and control, which most operations still lack.

The Path to Integration: Breaking Down the Silos

Breaking down operational silos requires a multi-faceted approach addressing both technical and organizational challenges. The most successful integration initiatives follow a structured pathway that delivers incremental benefits while building toward comprehensive integration.

Starting with Standards and Common Platforms

Effective integration begins with establishing common data standards across systems. This foundation enables meaningful communication even between diverse technologies.

“We couldn’t afford to replace all our disparate systems at once,” explains James, IT director at a manufacturing plant. “Instead, we started by implementing the ISO 18435 standard for diagnostics and maintenance integration across our operations. We required all new equipment and systems to support this standard and gradually added interfaces to legacy systems. This approach gave us a common language for integration without requiring massive capital investment.”

Successful standardization initiatives typically include:

Adopting recognized industrial standards like OPC UA, MQTT, or ISO/IEC standards

Implementing consistent asset naming conventions across all systems

Establishing uniform time synchronization across the facility

Creating standardized data models for critical information like equipment status, energy consumption, and production counts

These standards provide the foundation for more sophisticated integration efforts. They create a common language that allows different systems to share information meaningfully even when the underlying technologies remain diverse.

Building Cross-Functional Teams

Technical integration must be paired with organizational integration. Leading industrial operations are creating cross-functional teams specifically designed to bridge traditional departmental boundaries.

“We established our ‘Integrated Operations Center,’ with representatives from production, maintenance, quality, and facilities all working together with shared metrics and visibility across all systems,” shares Maria, operations excellence leader at a heavy equipment manufacturer. “This team doesn’t replace our traditional departments, but it provides critical coordination across boundaries. They’ve identified optimization opportunities worth millions annually that were invisible within our traditional structure.”

Effective cross-functional integration initiatives typically include:

Co-locating representatives from different departments

Establishing shared KPIs that encourage system-wide optimization

Creating communication protocols for system changes that might affect other areas

Developing integrated dashboards that provide visibility across traditional boundaries

Implementing regular cross-functional planning sessions for maintenance, production, and facility activities

These organizational changes help break down the human silos that often persist even after technical integration begins.

Phased Integration Approaches

Most facilities find that a phased approach to integration delivers the best combination of immediate ROI and long-term transformation. Rather than attempting to integrate everything at once, successful organizations identify high-value integration points that provide immediate benefits.

“We started small, connecting just our energy monitoring and production scheduling systems,” notes Thomas, a plant manager at an automotive supplier. “That single integration point saved us €240,000 in the first year by shifting energy-intensive processes to off-peak hours. We used that success to fund our next integration phase, connecting maintenance and production data to optimize preventive maintenance timing based on actual machine use rather than calendar schedules.”

Effective phased integration typically follows this progression:

Data visibility integration: Making data from separate systems visible in a standard interface, even before implementing control integration

Critical system pairing: Connecting two complementary systems that offer immediate efficiency opportunities (e.g., production scheduling and energy management)

Operational technology (OT) backbone: Implementing an industrial network that enables secure data flow between previously isolated systems

Analytics layer addition: Deploying cross-system analytics to identify optimization opportunities that aren’t visible within individual systems

Control integration: Enabling automated coordination between systems based on shared information and optimization algorithms

This phased approach delivers incremental value while building toward comprehensive integration. Each successful phase builds organizational confidence and often funds subsequent efforts.

Measuring Integration Success

Quantifying the benefits of system integration is essential for sustaining organizational commitment to these initiatives. Leading organizations establish clear metrics to track and communicate integration value.

“We established a dashboard specifically tracking our ‘integration ROI’ across multiple dimensions,” explains Jennifer, continuous improvement director at a pharmaceutical manufacturer. “This visibility helps us prioritize future integration efforts and maintain leadership support for these initiatives.”

Effective integration metrics typically include:

Reduction in problem resolution time for cross-system issues

Energy efficiency improvements from coordinated system operation

Decrease in quality issues related to system interaction factors

Reduction in unplanned downtime from improved early warning detection

Maintenance optimization savings from condition-based scheduling

Productivity increases from coordinated operations

A comprehensive global Plant Engineering study covering manufacturing facilities across North America, Europe, and Asia-Pacific found that facilities with highly integrated operations typically achieve:

15-20% reduction in overall energy costs

30-40% faster resolution of complex operational issues

25-30% decrease in maintenance costs through optimized scheduling

8-12% improvement in overall equipment effectiveness

5-8% increase in production capacity through system optimization

These quantifiable benefits provide the financial justification for continued integration investments.

Conclusion: The Integrated Operation Advantage

As industrial operations face increasing pressure to maximize efficiency, quality, and flexibility while minimizing costs, the limitations of fragmented systems become increasingly untenable. The organizations gaining competitive advantage are those systematically dismantling the silos that have historically separated their critical systems.

“The single most impactful change we’ve made in the past decade wasn’t a specific technology investment—it was breaking down the walls between our systems and departments,” reflects Michael, operations director at a consumer goods manufacturer. “When every system can share information with every other system, when every team can see how their decisions affect other areas, new levels of optimization and efficiency become possible.”

The journey toward integrated operations isn’t simple and doesn’t happen overnight. However, as the examples throughout this article demonstrate, even modest integration initiatives can deliver substantial returns while building toward the ultimate vision of truly connected industrial operations.

In today’s competitive global environment, the question isn’t whether your organization can afford to integrate its disparate systems. The question is whether it can afford not to.

This is the second in a four-part series examining industrial operations’ hidden challenges today. Join us next week for Part 3: “The Evolving Threat Landscape: Cybersecurity in Industrial Environments.”

Frequently Asked Questions about Industrial System Integration

Q: What are the typical payback periods for system integration investments? A: While results vary by facility, most industrial operations report ROI timeframes of 8-14 months for initial integration initiatives focusing on high-value connection points. More comprehensive integration programs typically achieve full payback within 18-24 months while delivering benefits for years.

Q: Do we need to replace our existing systems to achieve integration? A: No. Modern integration approaches focus on connecting existing systems rather than replacing them. Integration layers and industrial IoT platforms can bridge disparate technologies without requiring wholesale replacement of functional equipment or software.

Q: Which systems should we prioritize integrating first? A: The highest-value initial integration points typically connect production systems with either energy management or maintenance systems. These connections often reveal immediate optimization opportunities with quantifiable financial benefits that can fund further integration efforts.

Q: How can we justify integration investments to leadership? A: Successful justifications typically focus on quantifiable outcomes such as energy savings, reduced downtime, maintenance optimization, and quality improvements. Starting with a pilot project that demonstrates these benefits in a limited scope often provides the evidence needed for broader initiatives.

Q: What international standards should we consider for integration projects? A: Key standards to consider include ISO/IEC 62264 (enterprise-control system integration), ISO 18435 (diagnostics and maintenance integration), OPC UA (for secure data exchange), and IEC 61499 (for distributed control systems). The appropriate standards will depend on your specific industry and integration goals.

Here are the standard citation formats (APA-style) for the sources that support the claims in your blog post “Breaking Down Silos: The Integration Challenge in Industrial Operations”:

References

International Society of Automation (ISA)

International Society of Automation. (n.d.). ISA-95: Enterprise-Control System Integration. ISA.

McKinsey & Company – Industry 4.0 Use Cases and OEE

McKinsey & Company. (2022, May). Advanced manufacturing and the promise of Industry 4.0.

McKinsey & Company – Capturing Value at Scale

McKinsey & Company. (2022). Industry 4.0: Capturing value at scale in discrete manufacturing.

McKinsey & Company – Digital Performance and Collaboration

McKinsey & Company. (2020). Digital collaboration for a connected manufacturing workforce.

World Economic Forum (WEF) – Global Lighthouse Network

World Economic Forum. (2023). Global Lighthouse Network.

Plant Engineering Magazine – Maintenance & Integration Reports

Plant Engineering. (Various Years). Annual maintenance and integration surveys.

Business Development at Machine Intelligence Zrt. Innovation professional with 25+ years of experience in IT solutions and product strategy. Science history enthusiast and digital fabrication hobbyist specializing in 3D printing, laser cutting, and CNC. Holds MSc degrees in Chemistry and Physics from the University of Szeged.